About Sadales tīkls

Sadales tīkls (ST) is the largest electricity distribution system operator in Latvia, supplying electricity to more than 99% of households and businesses nationwide. Managing approximately 60,000 km of overhead power lines, the company is responsible for ensuring a safe, reliable, and efficient supply of electricity while maintaining one of the country’s most extensive infrastructure networks.

The Challenge: Manual Power Line Inspection Workflows

Currently, ST’s infrastructure inspections are carried out entirely manually by over 100 highly qualified field inspectors. These experts visually examined the network, detecting defects and assessing the technical condition of components based on their own experience and judgment. While effective, this approach is labor-intensive, time-consuming, and dependent on individual expertise, leading to variations in results. It also posed safety risks, as many inspections took place in remote or hazardous locations, from forests and swamps to hard-to-reach rural sites.

In addition to these operational challenges, ST faced a shortage of qualified personnel, especially younger electrical specialists willing to work in the field. The company saw a clear need to modernize inspections, introduce standardized methods, and shift toward a more data-driven, automated process.

Aerial data captured during the demo project, providing the visual input for inspection workflows.

Pilot Project Goals

At the start of the pilot project, ST aimed to enhance and modernize the inspection process by creating a data-driven workflow supported by innovative digital tools. Their specific goals included:

- Centralizing processes to establish a unified data management environment and improve data quality and accessibility for faster and more informed decision-making

- Developing intelligent support tools to assist inspectors within a digitally transformed working environment

- Reducing safety risks for personnel conducting inspections in difficult or hazardous areas (e.g., narrow clearances, swamps, wildlife, ticks, etc.)

- Implementing a standardized inspection approach by shifting from manual on-site inspections to a system based on digital imagery and analytics, suitable for power line inspection workflows

Ensuring consistency across regions so that defect detection does not depend on the inspector’s physical presence or location, and that inspections follow a uniform methodology throughout the entire network.

Field data collection setup used to capture visual information prior to analysis in Hepta Insights software

The Situation Before Implementation and Why Hepta Insights

Preventive maintenance at ST required the visual inspection of every segment of the overhead network once every four years, with results recorded in a GIS application and linked to planning and maintenance systems. While the process ensured regulatory compliance, it relied entirely on manual effort and human interpretation. This made it difficult to achieve consistent results across regions, slowed down data processing, and limited the company’s ability to take a predictive approach to overhead power line maintenance.

Through a competitive procurement process, the Hepta Insights solution stood out for meeting all technical specifications while offering the most cost-effective proposal. The platform aligned with ST’s operational needs and strategic goal of moving toward digitized and AI-supported power line inspections.

The Solution and Pilot Process: Introducing Digital Power Line Inspection Methods

Hepta provided a platform for processing aerial RGB imagery, detecting visible defects, and enabling centralized analysis. The pilot phase included collecting and uploading data, performing manual defect verification, and then applying automated detection algorithms to accelerate the process.

During testing, ST refined technical requirements, for example, defining a minimum number of images per asset for adequate coverage and setting resolution standards that allow detection of defects as small as 2 cm. These measures improved data quality and laid the groundwork for consistent automated analysis.

Although the solution is not yet integrated into ST’s daily workflows, the pilot successfully demonstrated the feasibility of AI-assisted power line inspection in real-world conditions. Aerial perspectives revealed defects that could easily be missed from the ground, such as conductor binding issues, pole cap damage, and insulator cracks. The potential benefits include faster inspections, reduced resource requirements, and enhanced decision-making through richer visual data.

Although no full-scale metrics have been measured yet, early results suggest that once integrated, the solution could deliver significant gains in efficiency, cost control, and operational safety.

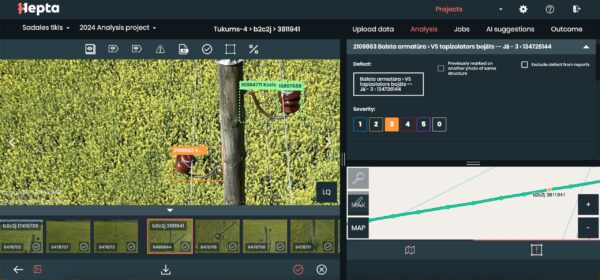

Defect detection workflow in Hepta Insights, showing insulator damage marked on aerial imagery with severity classification. Read more about how severity levels are defined.

AI-Assisted detection of pole top defects in Hepta Insights software

Collaboration Experience and Future Outlook

ST describes the collaboration with Hepta as highly professional, responsive, and proactive. The team consistently identified potential risks early, validated solutions before implementation, and adapted functionalities based on user feedback. Several of ST’s recommendations, such as adding custom report fields and advanced filtering criteria, have already been incorporated into the product roadmap, demonstrating an open and agile approach to development.

Looking ahead, ST’s priority is the full digital transformation of the inspection process, with AI-driven defect detection for power lines at its core. The company aims to reduce reliance on manual workflows, improve the accuracy and consistency of assessments, and move toward a predictive maintenance model. Once fully integrated, such a solution is expected to play a key role in achieving these goals, supporting scalable, safe, and efficient infrastructure management for years to come.

Key Takeaways from the Pilot Project

- Validated the feasibility of AI-assisted power line inspection: The pilot project confirmed that aerial RGB imagery and automated detection algorithms can support more consistent and scalable inspection workflows without replacing existing processes.

- Demonstrated the value of a unified digital workflow: The pilot showed how centralizing visual data and inspection results into a single environment can reduce manual steps and improve the quality and accessibility of information used in maintenance planning.

- Enhanced visibility into overhead power line defects: Aerial viewpoints revealed issues, such as binding defects, insulator cracks, and pole cap damage, that are often difficult to detect during traditional ground-based inspections.

- Improved safety conditions for field personnel: By shifting part of the inspection effort from on-site visits to remote visual analysis, the demo highlighted the potential to reduce inspector exposure to hazardous terrain and hard-to-reach areas.

- Established a foundation for future predictive maintenance workflows: While still in the demo phase, the project demonstrated how standardized imagery, digital data, and AI-supported analysis can pave the way for more consistent, region-wide inspection practices across ST’s overhead network.